Plug & Power™ is a revolutionary new way of making Power Distribution Boards and Motor Control Centers! A Techno Module panel with Plug & Power™ can be modified, changed and rearranged indefinitely, while maintaining your power supply to critical equipment.

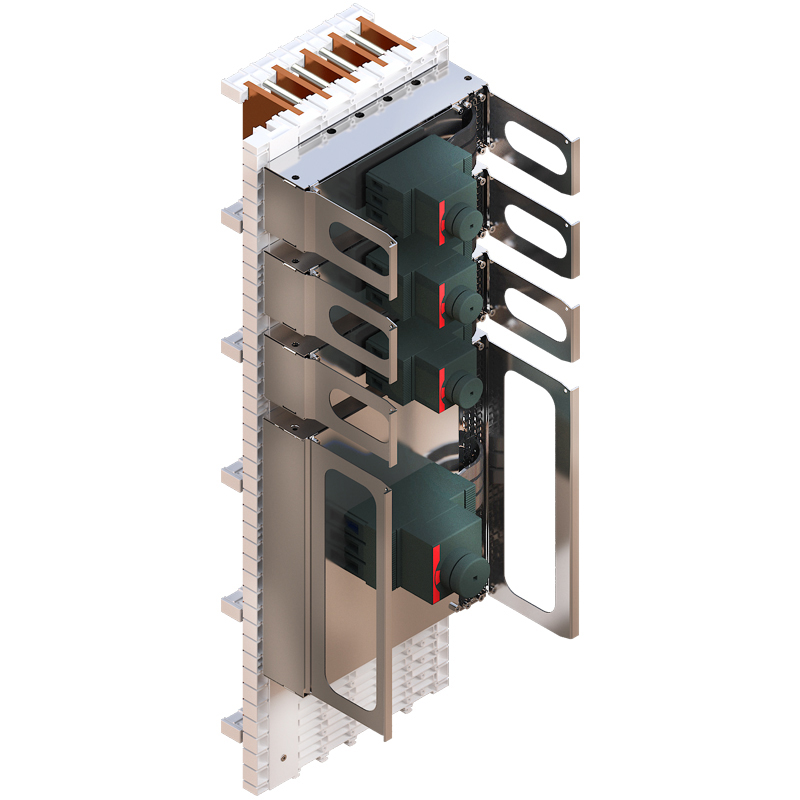

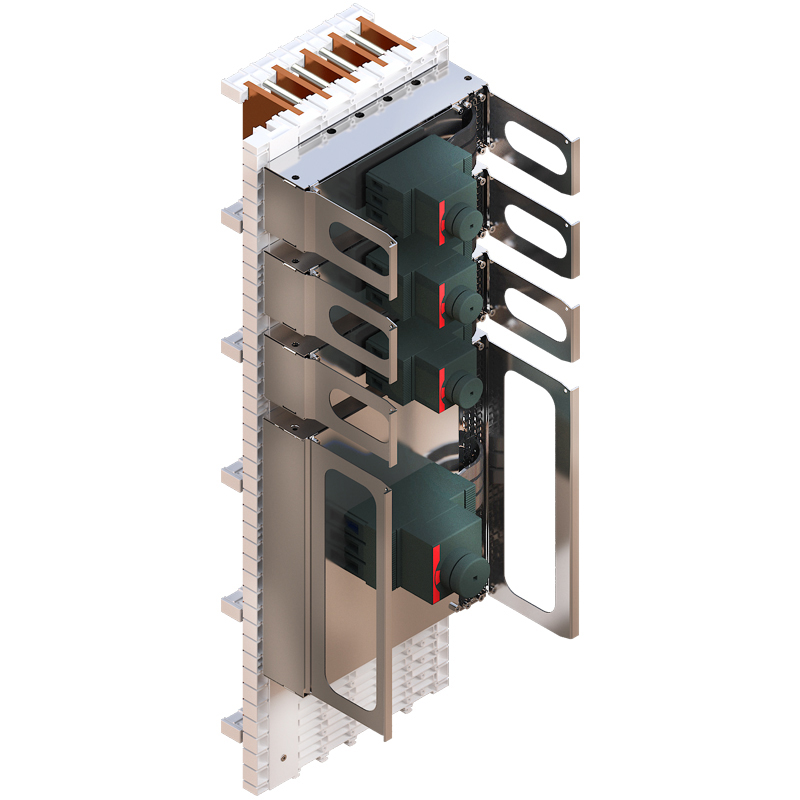

The vertical busbar risers & droppers are mounted in a unique busbar holder, this doubles as a Form 4 separation plate and a plug-in base. We call it the motherboard. These motherboards run the entire height of each Plug & Power™ section.

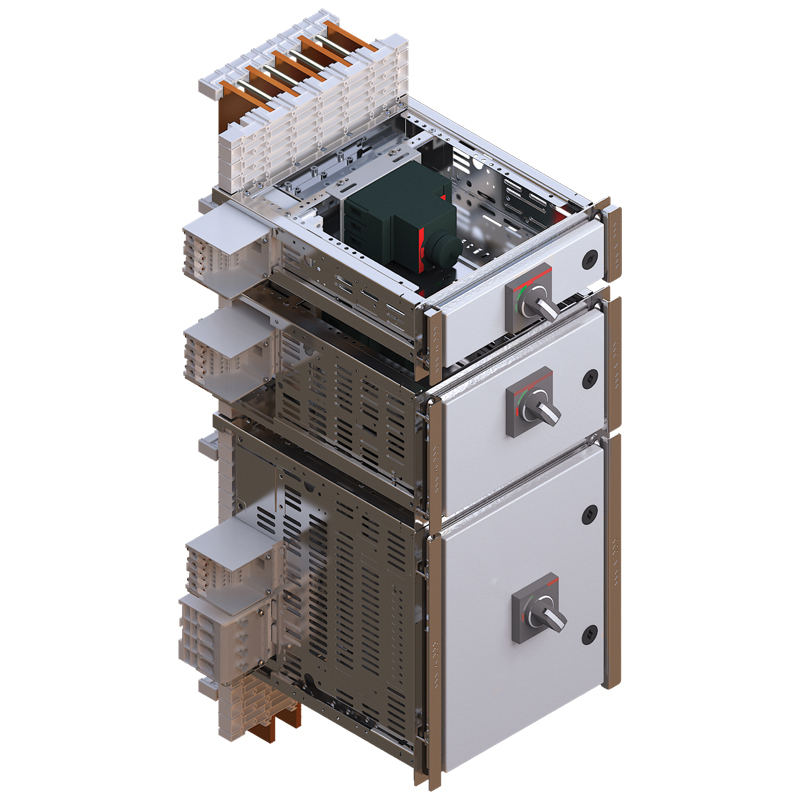

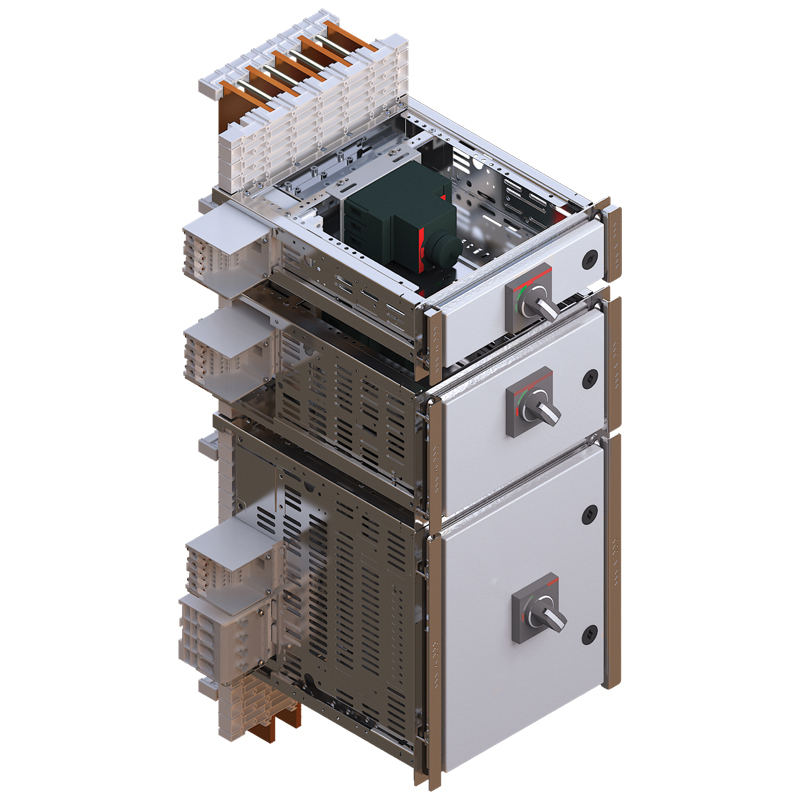

The removable or withdrawable unit can be inserted anywhere within the section, with its power plugs connecting directly onto the busbars mounted on the back of the motherboard. Outgoing plug connection units can be mounted on either the right or the left side of the unit providing maximum flexibility for custom cable connections and common cableways. This reduces the overall length and cost of your panel.

Each section busbar can carry 1250 Amp, so there is sufficient space for a variety of different sizes & ratings of withdrawable and removable units. While designing your future Plug & Power™ panel we recommend having at least 30% free space for expansion. For example: should the hospital require an extra scanner, the shopping mall needs to open an additional shop, the ice cream factory needs to install another compressor, the oil & gas platform needs a pump upgrade etc. Simply remove a blanking plate and install an additional unit in minutes!

Plug & Power™ is the freedom to Plug in and Power up, anywhere you like, at any given time.

Plug & Power™ has furthermore been designed for easy and quick assembly, so the panel builder saves a considerable amount of time in the workshop. The labor cost of bolting connections to busbars from circuit breakers and motor starters is higher compared to just plugging them in. Outgoing circuits for power distribution and motor starters can be conveniently pre-assembled on a work table and simply plugged into the panel.